3 In Gauge For Expansion And Contraction In Siding

In this arti cle i ll explain the methods contractors should use to avoid callbacks.

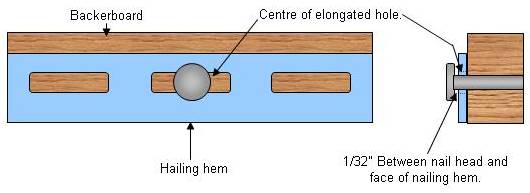

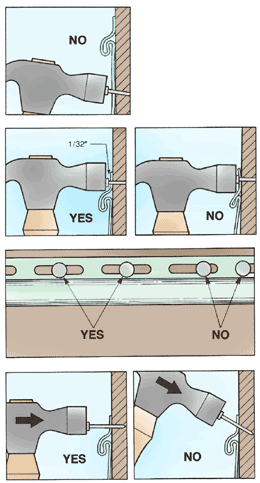

3 in gauge for expansion and contraction in siding. The nails should always be in the center of the slot as shown in figure 2 there is one exception which will be discussed later that is provided in the nailing hem. Longitudinal cote 6 7x10e 6 in in f transverse cote 7 65x10e 6 in in f. Allowance should be made for expansion and contraction by leaving a 1 4 6 4mm gap between the siding and all corner posts and channels. The following expansion values should be used for considering this type of movement.

Increase to 3 8 9 5mm when installing in temperatures below 40 f 4 4 c. If the panels are 20 feet 6 1 meters or longer refer to the manufacturer s instructions for how to increase the gap. Nail through the top flange which is the longer of the two flanges. Screws should be size 8 truss head or pan head corrosion resistant self tapping sheet metal screws.

Use a nail gun with 18 gauge 1 3 4 long brad nails. On the first board a second nail should be placed approximately 1 from the bottom edge. Expansion and contraction should be taken into consideration when roofing with steel. James hardie recommends designing for this type of movement on buildings with long runs of continuous siding.

Mdf like other wood products with absorb and desorb moisture with changes in humidity. Level the playing field in most cases siding should be installed level. Loose siding panels or wavy siding. Not less than 16 gauge semi flattened to an elliptical cross section.

Skyline roofing and the sterling roof system have clips available for long length applications. Can be used if the screws do not restrict the normal expansion and contraction movement of the panel on the wall. Over 90 of these problems are because of fastening methods that do not allow the vinyl and aluminum products to expand and contract freely. Vinyl siding has to have room for expansion and contraction.

The following table provides the coefficients of linear thermal expansion and representative thermal expansion values for various building materials where possible the values were taken directly from manufacturer technical data sheets and reflect the coefficients of linear thermal expansion for specific representative products. 15 gauge round head for 1 2 beadboard only fasteners should be a minimum of 1 1 2 in length fastening expansion contraction azek trim and moulding products expand and contract with changes in temperature. Properly fastening azek trim and moulding material along it s entire length will minimize expansion and contraction.