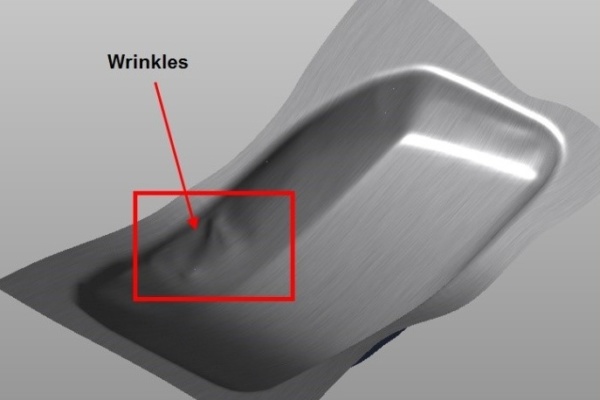

Wrinkle Defect In Sheet Metal

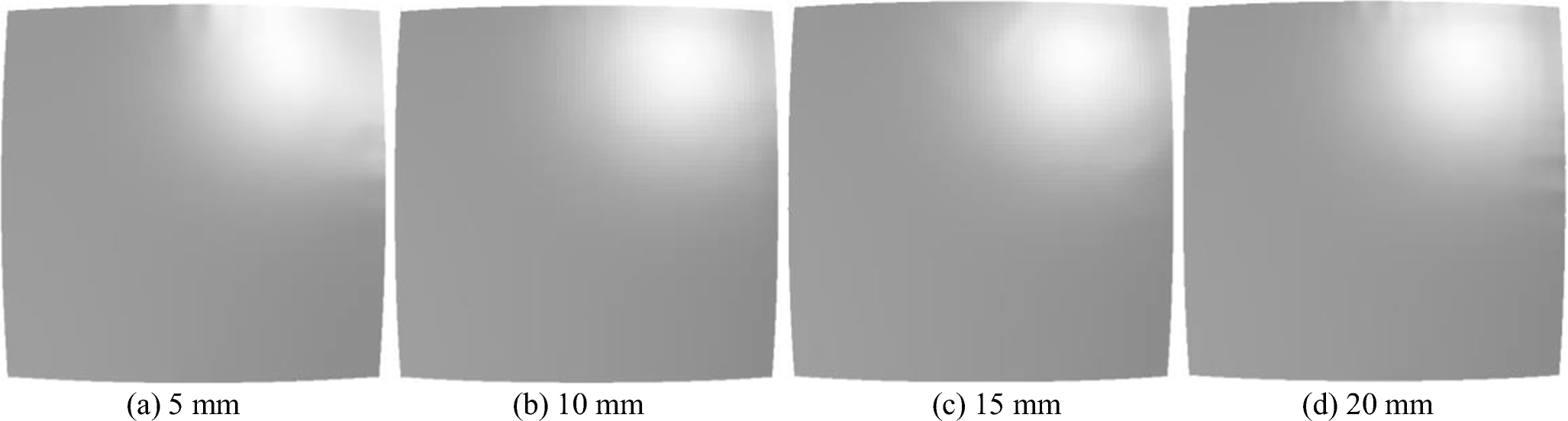

The greater the minimum half cone angle of the roller path the worse the formability of the sheet metal considering wrinkling defect.

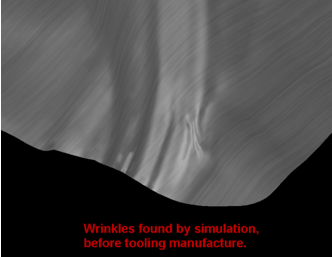

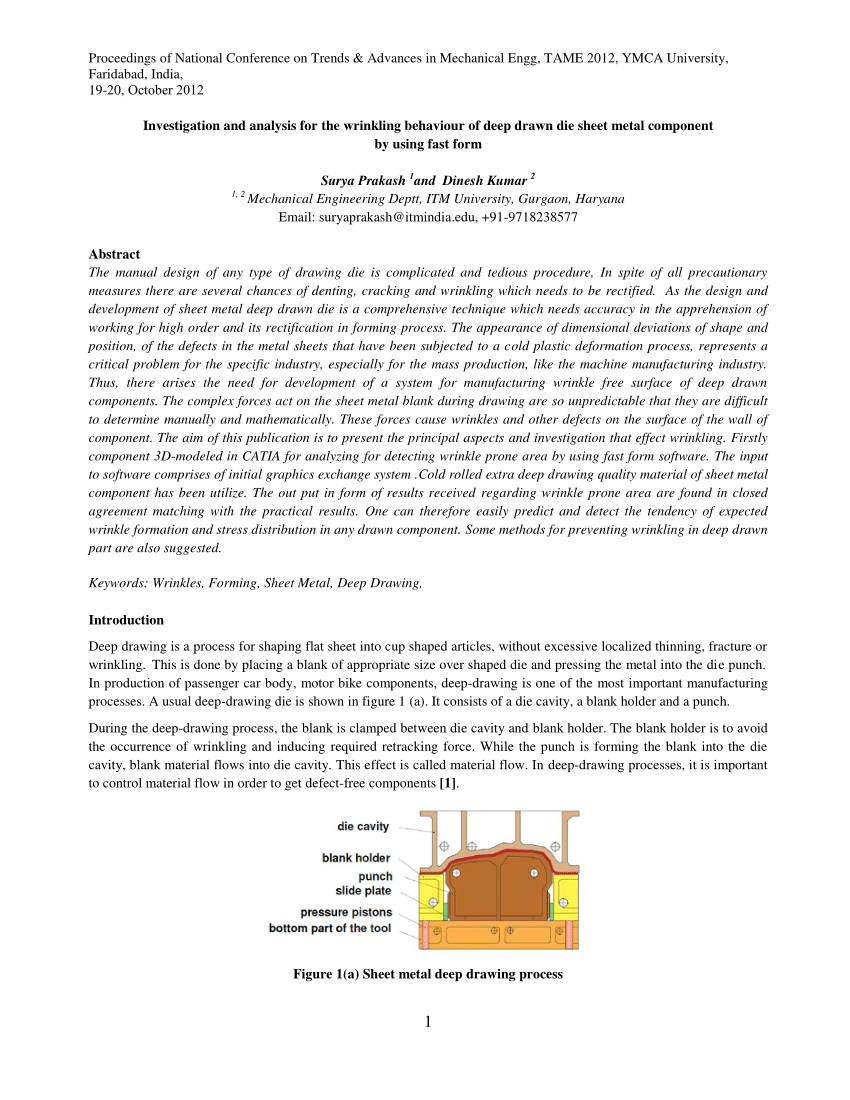

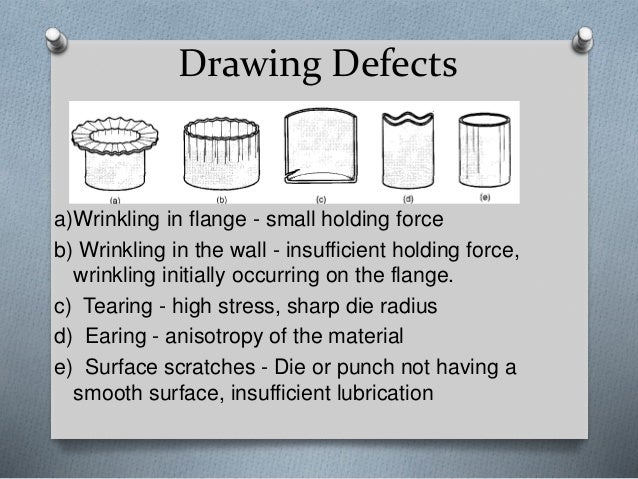

Wrinkle defect in sheet metal. During this process the blank sheet will develop defects if the process parameters are not selected properly. Failure of sheet metal parts during deep drawing processes usually takes place in the form of wrinkling or. This restraining action is largely applied through friction. The most common sheet metal stamping defects are also the easiest to predict using advanced simulation software such as autoform.

The flange of the blank undergoes radial drawing stress and tangential compressive stress during the stamping process which sometimes results in wrinkles. Choosing the wrong size blank under estimating the number of forming tools required or encountering an unexpected wrinkle or split can be very costly if only discovered during first physical tool tryout. Sheet metal forming wrinkling deep drawing experimentation finite element method date received. One of the primary defects that occurs in deep drawing operations is the wrinkling of sheet metal material generally in the wall or flange of the part.

Thickness to diameter ratio is a main factor used to quantify the geometry of a blank and can be calculated by t d b. In sheet metal forming a blank sheet is subjected to plastic deformation using forming tools to achieve the designed shape. 10 derived a wrinkling criterion for sheet metal with a normal constraint using the energy method and effectively predicted the onset of the wrinkling defect. On the sheet supplies a blank holding force which controls the metal flow.

Among the limited publications of investigating formability of sheet metal considering wrinkling defect research efforts have mainly focused on the determination of sheet and tube bending formability. For noncircular sheet metal parts the maximum diameter is sometimes used. Phenomena of instability which appear during the process of deformation compression instability being one of them. The predicted results.

Excessive flow may lead to wrinkles 2 within the part.